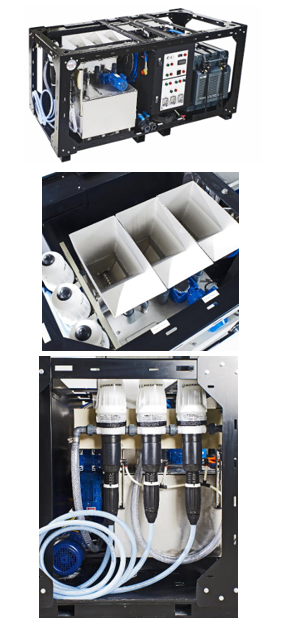

XS-01 SYSTEM

Compact diesel-powered self-contained decontamination unit. It is designed to fit easily and without modification onto the back of a pick-up truck or onto a flatbed trailer. It can be used by 1 or 2 operators for CBRN decontamination on vehicles, equipment or infrastructure. It is quick and easy to use and carries enough water and NEOSAN LABS CBRN Decon Solution for an urgent intervention after a CBRN incident.

The XS-01 system uses an innovative technology to apply ready-to-use NEOSAN LABS CBRN Decon Solution. The Decon Solution is supplied in drums ready to slot into the system for direct use with no need for unpacking or mixing. The system includes an air compressor allowing the use of low liquid fraction foam. Optional features that can be added to the system include: use of hot water, use of dilutable decontamination solutions (powder or liquid).

SPECIFICATIONS

Mass: 560 kg (empty), 940 kg (with all tanks full)

Dimensions: 1.5 m x 1.35 m x 1.3 m

Cold water generation: 660 L/h, 80 bars

Payload: 250 liters of water, 130 liters of DF200 HF

1 automatic high pressure water hose. Length 30 m

1 automatic hose reel for chemical solution, length 30 m

Set of lances

MODULE N-01

Autonomous system for vehicles decontamination by chemical neutralization.

FEATURES

Main components:

• Metal structure,

• Water tank with a capacity of 125 L with a visual level gauge,

• Diesel generator

• 1 mixing unit, composed of:

1 chemical tank with a capacity of 80 L and a visual level gauge,

2 electric elements to heat the liquid inside the tank,

1 agitator,

1 access trap allowing the manual changing of the decontamination solution,

• 1 dosing unit for powder concentrate, containing:

Three 10L hoppers,

A motor-driven screw feeder per hopper.

• One dosing unit for liquid concentrate, comprising:

A compartment that can hold three 10L container,

One non-electric dosing pump per can.

• 2 reels with 30 m hose,

• 1 control panel,

• A place for a 20 L can,

• A set of lances and accessories,

• A waterproof protective cover.

Main benefits:

• 1 chemical pump that draws from the mixing unit and supplies the hose reel,

• Capable of dosing 3 liquid concentrates and 3 powder concentrates

• The mixed solution can be heated up to 60°C

• Usable on the ground as stand-alone or integrable on carrier

• Usable by 1 or 2 operators

• Quickly transportable by manual pallet jack, forklift, or crane.

• Runs on diesel

SPECIFICATIONS

Dimensions (L x l x h): 2200 x 960 x 1050 mm

Total weight: 800 kg (all tanks full)

Power and water autonomous

Generator fuel tank capacity: 20 liters

Continuous electrical generator power: 8 kW

Liquid dilution rate: 5 – 25 %

Hopper capacity: 10 liters

Pump output pressure: 6 bars

Pump Flow setting range: 3.5 L/min – 14.7 L/min

• FLEXIBLE USE

• AUTOMATED DOSING SOLUTION

• CHOOSE YOUR DECON SOLUTION AT THE LAST MINUTE

Decontamination solution heating temperature: 60°C

MODULE D-01

Autonomous system for vehicles decontamination by toxic displacement, using hot water pressure. It can

to be used in pre-treatment or post-treatment.

FEATURES

Main components:

• Métal structure,

• Water tank with a capacity of 240 L with a visual level gauge,

• Hot water high-pressure washer: HDS 1000 DE (Kärcher),

• 2 reels with 30 m hose,

• Set of lances and accessories in a storage box,

• Place for a 20 L container,

• Free space for storage,

• Waterproof protective cover,

Main benefits:

• Usable by 1 or 2 operators

• Runs on Diesel

• Usable on the ground as stand-alone or integrable on carrier

• Quickly transportable by manual pallet jack, forklift, or crane.

SPECIFICATIONS

Dimensions (L x l x h): 2200 x 960 x 1050 mm

Weight: 840 kg (all tanks full)

Energy and water autonomous

Engine fuel tank capacity: 5.5 liters

Generator power: 7.4 kW

Burner performance: 59 kW

Burner fuel tank capacity: 34 liters

Max flow (1 lance): 10 L/min – 600 L/h

Max flow (2 lances): 14 L/min – 840 L/h

Max pressure (1 lance): 190 bars

Max pressure (2 lances): 160 bars

Max water temperature with burner: 98°C

Max fuel consumption (burner): 5.6 L/h

MODULE D-02

Autonomous for vehicles decontamination by toxic displacement, using cold water pressure. It

can be used in pre-treatment or post-treatment.

FEATURES

Main components:

• Metal structure,

• Water tank with a capacity of 240 L with a visual level gauge,

• Cold water high-pressure washer running on diesel: MC 5M-195/1000 DE

(Nilfisk),

• 2 reels with 30 m hose,

• Set of lances and accessories in a storage box,

• A place for a 20 L container,

• Free space for storage,

• Waterproof protective cover,

Main benefits:

• Usable on the ground as stand-alone or integrable on carrier

• Usable by 1 or 2 operators

• Runs on Diesel

• Quickly transportable by manual pallet jack, forklift or crane.

SPECIFICATIONS

Dimensions (L x l x h): 2200 x 960 x 1050 mm

Total weight: 850 kg (all tanks full)

Energy and water autonomous

Engine fuel tank capacity: 5.5 liters

Engine power: 7.4 kW

Max flow (1 lance): 12 L/min – 720 L/h

Max flow (2 lances): 13 L/min – 780 L/h

Max pressure (1 lance): 190 bars

Max pressure (2 lances):80 bars

SYSTEM M-01

CBRN vehicles decontamination:

• Apply hot water or vapor at different pressure or flow levels,

• Dose, mix and spray decontamination solutions (concentrate liquid, non concentrate liquid or powder),

• Carry water, decontamination solutions, and various accessories.

Includes:

• MERCEDES UNIMOG UGE527,

• Specific adaptation chassis,

• ESSENTIAL DECON D-03 module,

• ESSENTIAL DECON N-02 module,

• Integration kit ESSENTIAL DECON M-01.

FEATURES

Autonomous system

Usable by 1 to 3 operators simultaneously

Suitable for use with NEOSAN LABS DF200 foaming decon solution

Compatible with decon solutions, powder or liquid form (diluted or not)

Runs on Diesel

Hight mobility all terrains

Initial supply of water and decon solutions to decontaminate 3 or more vehicles

Limited implementation and fallback time

1 Electrical cabinet accessible from the ground

Ability to refuel the water tank from an external source (motor pump)

Pre-treatment also possible by motor pump and fire hose.

SPECIFICATIONS

Weight: 8.9 t (empty), 12 t (all tanks full)

Dimensions: 6.85 m x 2.3 m x 2.9 m

Hot water: 2400 l/h, 98°C, 140 bars

Steam: 1200 l/h, 155°C

Pay load: 2750 Kg of water, 400 Kg of DF 200

Shower output: 1 200 l/h, adjustable temperature around 30°C

Chemical mixing tank capacity: 200 L

2 high-pressure water and steam hoses (30 m long each)

1 hose for decon solution with a length of 30 m

Set of lances: 3 standard, 3 short, 2 under vehicles, 1 fire hose.

MODULE D-03

Vehicles decontamination by toxic displacement,

using hot water pressure. Also, treat toxic contaminants with steam.

It can be used in pre-treatment, treatment, or post-treatment.

FEATURES

Main components:

• Metal structure,

• Water tank with a capacity of 2750 L and a visual level gauge,

• Hot water high-pressure washer running on electricity: HDS 12/14-4

(Kärcher),

• 2 reels with 30 m hose,

• Set of lances and accessories.

Main benefits:

• Integrated solution

• Electric and Diesel powered,

• Compacity

• High level of thermal and hydraulic power

• Usable by 1 or 2 operators,

• Usable from the ground when integrated on carrier

SPECIFICATIONS

Dimensions (L x l x h): 2200 x 2200 x 1500 mm

Total weight: 1 180 kg (empty), 3 980 kg (all tanks full)

Hydraulic interface usable from the ground,

Boiler power: 170 kW

High pressure pump power: 15 kW

Max water flow (2 lances): 40 L/min – 2400 L/h

Max steam flow (2 lances): 20 L/min – 1200 L/h

Max water pressure: 140 bars

Max water temperature: 98°C

Max steam temperature: 155°C

2 x 30 m reels

Shower output: 1 200 l/h, adjustable temperature +/- 30°C

MODULE N-02

Vehicles decontamination by chemical neutralization.

FEATURES

Main components:

• Metal structure,

• 1 mixing unit, including: 1 chemical tank with a capacity of 200 L, and a visual level gauge, 1 agitator, 1 access trap allowing the manual dosing of the decon solution,

• 1 chemical pump that draws from the mixing unit and supplies the hose,

• 1 30 m hose,

• 1 control panel,

• Set of lances and accessories,

• Storage area for decontamination solutions and equipment.

Main benefits:

• Capable of using several chemical decontamination solutions: powders, concentrate, or liquids.

• Usable from the ground when integrated on carrier

• Usable by 1 operator

• Electric and pneumatic powered

SPECIFICATIONS

Dimensions (L x l x h): 2200 x 960 x 1050 mm

Total weight: 390 kg (empty), 870 kg (all tanks full)

Chemical pump output pressure: 6 bars

Chemical pump flow: 4 L/min

Storage capacity: 160 L of DF200

Moto-pump flow: 500 L/min